With IFS Cloud, enterprises are able to get an end-to-end picture of the state of health of their industrial assets especially around periodic cycles of maintenance explains Vijay Jaswal at IFS.

There is one constant in the modern industrial world and that is everything is constantly changing. As a direct result of this, a business can expect its customer’s preferences and requirements to evolve, and this is where both a challenge and opportunity, lie for businesses.

Businesses across verticals are eager to reduce complexity, costs, and risks while earning customer loyalty and bolstering margins. This is where cloud-based enterprise software can play a key role, by empowering companies to plan, manage and optimise critical asset availability, service delivery and workforce productivity.

Thanks to enterprise software’s ability to deliver value to customers, the market is healthy and expected to grow across the next decade. According to Precedence Research, the global enterprise software market was estimated to be worth US $201 billion in 2022, and is projected to be worth $610 billion, with a CAGR of 12% from 2023 to 2032.

Vijay Jaswal, IFS’ CTO for Middle East, Africa and Asia Pacific Japan, says all it takes is a full-feature single platform to transform a business and enable it to deliver results where it really counts, at the moment of service.

IFS platforms orchestrate connections between people, process, systems and assets, to provide a moment of service to a business customer when it matters the most.

IFS Cloud

IFS Cloud helps companies engage customers, empower employees and optimise assets. There are three key capabilities within the IFS Cloud solution – enterprise asset management EAM, field service management FSM, and enterprise resource planning ERP.

“The first two elements EAM and FSM, is what IFS is particularly good at,” says Jaswal. “And ERP fills the spaces in between.”

From an IFS EAM perspective, it is about managing an asset from procurement to retirement. An asset can be anything from a machine to a valve to an old refinery to a car or even a building. Naturally, during the lifetime of the asset, it will require maintenance so it can keep serving the business.

This is where IFS FSM comes into the picture. FSM is about ensuring the right person with the right skillset, with the correct spare part, and with the correct tools to conduct the installation, is available at the right place and the right time. If one of those elements things is missing, the system can halt with significant losses.

IFS ERP fills in the gaps when several elements need to be organised. Parts need to be sourced by procurement and human resources is responsible for the sourcing of engineers. These aspects are managed by ERP.

Over the years, IFS has leveraged EAM, FSM and ERP and delivered bespoke solutions to customers who have in-turn used the solution to generate additional revenues by developing and rolling out servitisation strategies on their products.

“With IFS Cloud solution, IFS can work with businesses in all these verticals. In fact our teams have been working to push this native cloud architecture, which makes all the different IFS modules available to customers.”

And that is the key, indicates Jaswal. IFS is empowering customers to switch on and select certain modules only when they are ready for it.

Unlike other companies in the enterprise software space whose model includes building relationships with specifics vendors and OEMs, IFS has opted for an open API approach with devices. Where IFS does engage with third parties is in data analytics, to provide an end-to-end solution for its customers.

From an integration perspective, IFS has relationships with a number of providers like Boomi, But for analytics and when it comes to big data, IFS partners with third-party providers to deliver that service. This is particularly in cases where the velocity and volume of data is great.

Market focus

IFS focuses on six key verticals across the globe: aerospace and defence, energy utilities and resources, construction and engineering, manufacturing, service industries, and telecommunications. IFS has substantial vertical expertise in these segments, which enables it to fully understand its customers and deliver value. However, IFS does have the most experience in manufacturing, followed by aerospace and defence.

“One of our consultants, for example, has spent twenty years in an air force engineering department and with that IFS has deep knowledge of that vertical. Similarly, when IFS had a meeting with a regional airline its aviation expert flew in. Whenever IFS is talking to customers, there are people inside IFS who know their stuff and have a deep perspective on that vertical,” says Jaswal.

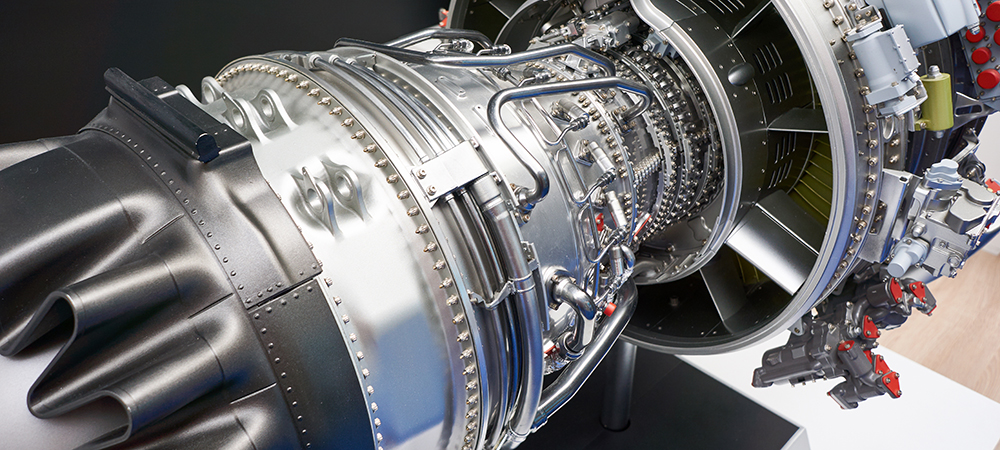

Looking at the aircraft engine maintenance, that is quite a complex process. Engines have thousands of parts and to empower its customers, IFS has created specific solutions for those areas, which is why airlines and airplane engine manufacturers work with IFS.

A few years ago, Rolls Royce created an intelligent engine, which means there is a load of sensors sitting in the engine that take readings, collect data and send the information back to Rolls Royce. Rolls Royce can then analyse the data, reach out to customers, and provide valuable data-driven intelligence.

What Rolls Royce has done is servitised that engine and created an additional revenue stream. They can get the analytics, and they can inform the airline when an engine needs to be cleaned, given general maintenance, or a specific part needs to be changed.

The ability of IFS to build solutions that give customers this ability to understand and predict what is going on in different scenarios, is part of the vendors value offering. Data collection from sensors is a critical part of the process. Rather than going down the route of building sensors for different applications, IFS relies on an Internet of Things. IoT connector that allows the vendor to connect a device or a multitude of devices. The IoT connector is key to the whole process.

Automation and AI

For asset management in these types of scenarios, the market is moving towards automation and devices rather than an engineer or technician picking up the phone and saying, please send us support because this part has stopped working.

Sensors within an asset such as an engine or a manufacturing plant are sending out data at pre-determined intervals and can trigger a support request. The IoT connector that IFS has can connect to the device, ingest all the information, and compare it to historic information. Through such comparisons, the IFS EAM and FSM modules knows when an engineer needs to be sent out and when something is about to fail or not.

IFS FSM module is also capable of managing complicated service scenarios where there may be thousands of engineers, different addresses, and multiple parts. IFS relies on its own AI and machine learning technology to provide additional value to customers.

“If you look at a field engineer’s day, it could involve picking up parts, tools, and even additional engineers that may be needed for expertise,” says Jaswal.

AI can make a big difference here, which is why IFS has integrated an AI engine into its FSM solution. When you combine sensor, IoT information with machine learning and AI, it not only gives you the kind of pre-emptive maintenance capability, but it also extends into things like digital twins.

Servitisation

With digital twins you can have a digital version of an engine, a machine or even an entire manufacturing facility and an oil refinery.

Combining IoT data with AI opens up a lot of possibilities. With a digital twin at your disposal you can look at what extremes you can push a particular machine to before it breaks; what is the most optimum fashion to use it, so it requires the least maintenance; what is the current health of key components.

Jaswal sees significant opportunities for businesses to embrace servitisation and develop revenue streams by leveraging cloud-based enterprise software solutions.

“It is still early days for many verticals to consider the servitisation model but when it comes to assets that need to be maintained and operated efficiently over its entire lifecycle, I think servitisation is truly relevant to those industries,” points out Jaswal.

Click below to share this article